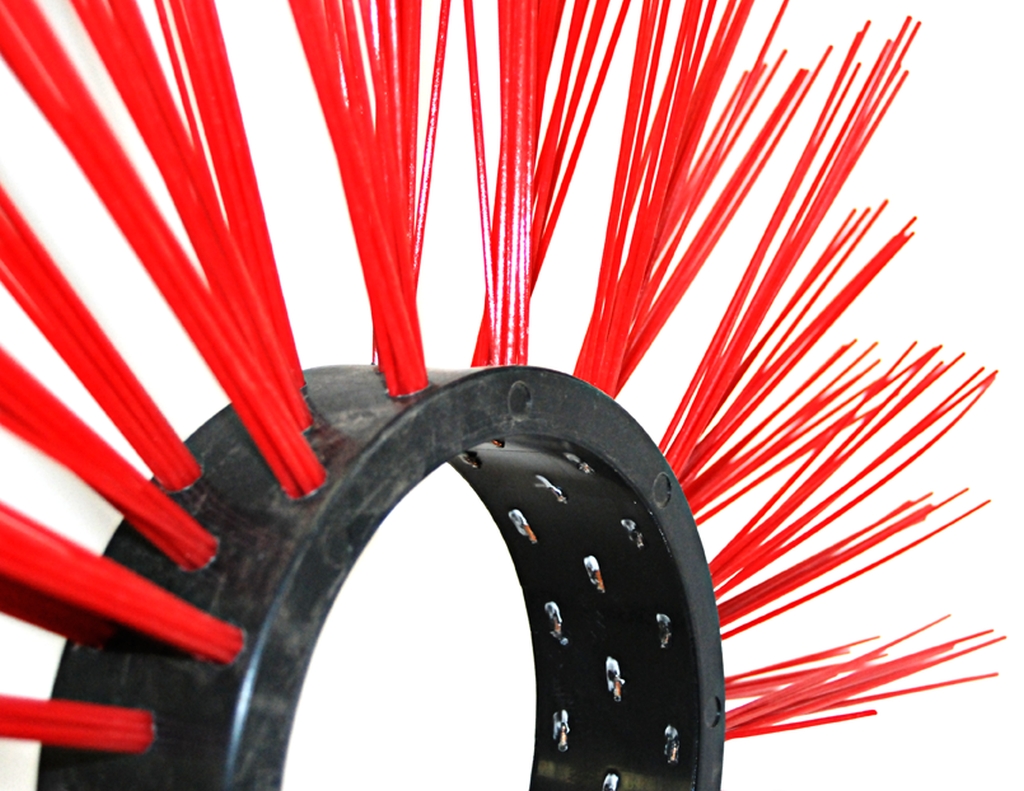

Brush Rings

Disc brushes for sweepers consist of a metal ring into which the bristle material is pressed or plastic rings into which the bristle material is welded. The brush rings are used to form a roller brush or sweeping roller. This is done by placing several brush rings on a machine core. This allows the design of the roller brush to be determined.

Advantages of brush rings rings for sweepers:

- The assembly and disassembly of brushed off brush rings is quick and easy.

- Broom rings do not rust on the support tube and do not jam due to their width.

- No distance rings are needed.

- An even sweeping pattern over the entire period of use ensures a consistent cleaning effect. Even towards the end of the service life, there are no dirt streaks when sweeping.

- The bodies of the broom rings can be fitted as required. Depending on the customer's requirements, a denser fill can be produced than with disc brooms, with approx. 50% higher fibre content, or a lower fill thickness.

- The core of the machine can always be completely filled, regardless of the length of your type of machine.

Broom rings are pushed onto support tubes and thus become fully functional rollers.

Broom rings can be equipped with all common trim materials:

- Polypropylene (corrugated or smooth and fine or coarse) is suitable for all types of soiling.

- Nylon is suitable for all types of soiling. Nylon is particularly abrasion-resistant and therefore has a long service life.

- Corrugated wire is suitable for paved surfaces and stubborn dirt.

- Mixed trim

Broom rings are available with inner diameters of 78, 110, 128, 178 and 254 mm.